The foundation for all our tillage and cultivation products.

From single to five bars, rigid to stack fold, Bigham bars hold up under the toughest conditions.

Rigid Bars

Rigid Tool Bar With Triple Tubes

Bigham rigid tool bars suit virtually every need, with one, two, three, or four lower frame tubes. Available options complement light to very heavy operations. Since 1985, the Diamond Mast Tool bar has proved its durability and value with the best reputation in the business.

Vertical Fold Tool Bars

Bigham Vertical Fold Tool Bars give you an economical way to reduce your transport width with legendary Bigham quality.

Available in double 7×7” bars to triple and quad bars with combinations of 4×7” and 4×4” tubes, these tool bars give you the flexibility to outfit wide tools you can safely transport.

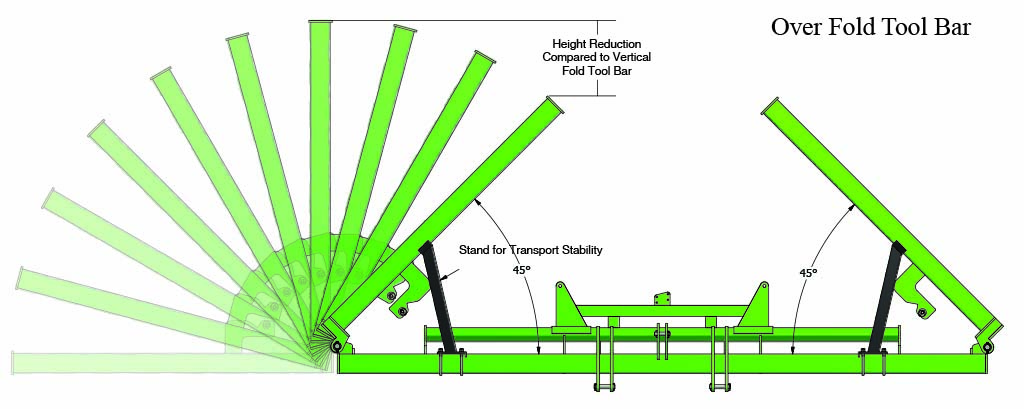

Over Fold Tool Bars

Bigham Over Fold Tool Bars give you an economical way to reduce your transport width and height with legendary Bigham quality.

Available in double 7×7” bars to triple and quad bars with combinations of 4×7” and 4×4” tubes, these tool bars give you the flexibility to outfit wide tools you can safely transport.

Wings fold inward past the ninety degrees normal vertical fold toolbars travel, up to another forty-five degrees past vertical, reducing your transport height for safety when passing under bridges and electrical wires.

Adjustment is provided to allow the wing to “droop” below horizontal from five to fifteen degrees, allowing the unit to conform to terraces and other surface irregularities.

Wing stands provided additional stability when traveling with wings raised.

Stack Fold Tool Bars

The Series III Low Profile Stack Fold Tool Bar with patented Stack Lock® wing transport feature incorporates new elements and design concepts that are unique in the industry. Frames with 7×7” front and rear members support heavy tillage applications and lift requirements for planter units. Minimum height and width transport specifications add safety and convenience provisions for large scale farming operations.

Single Bar Stack Fold Tool Bars

Bigham Stack Fold Tool Bar technology with patented Stack Lock® wing transport feature is now available in a single bar frame. The single-bar construction gives you several benefits:

• Lower cost

• Reduced weight and less need for lift-assist wheels

• Mounts closer to tractor for better lifting leverage

It is recommended for lower load and torque applications such as:

• Planter

• Lilliston Cultivator

• Model 889 Cultivator (up to 12 row)

Standard Features on Rigid Tool Bars

Superbar II Tool Bars (Triple Bar & Double Bar) are constructed with a diamond mast, which distributes load and stress between lower tubes and stiffens the bar. For bars subjected to unusual load or stress, heavy duty options are available in both the triple and double bar designs. On the heavy duty tool bars, 4 x 4 x 3/8” tube is substituted for 1/4” tube on all lower bars for extra strength. Strap steel is formed to give a 360 degree weld around lower bars.

All-purposed triple bars are spaced for a variety of functions: Cultivators or planters, ripper plows, chisel plows and many others.

Standard Features on Vertical Fold Tool Bars

Standard Features on Over Fold Tool Bars

Standard Features on Stack Fold Tool Bars

• Outboard wing brace adds stability to the upper structure during transport. Brace is also a key component to achieve minimum (Low Profile) transport height.

• All pivot pins are 2” diameter and equipped with greasable bronze bushings for long life in the field.

• Patented Stack Lock® transport lock joint keeps upper wing structures stable during transport.

• Pivot lugs and other parts subjected to load and wear are cut from Formalloy 400 plate.

Bigham Tool Bars are made to suit just about any application, and we custom-design for special applications.